T238 vision is to become an interesting company, with a mission to continuously output creativity and fun!

T238 QRBLS-480 Brushless Motor Basic Edition

Next-Gen Brushless Power for Every Mission

The T238 QRBLS-480 Brushless Motor Basic Edition is built for serious AEG and gel blaster players seeking high performance without complexity. As the entry-level model in the T238 brushless lineup, it delivers smoother operation, improved efficiency, and lower heat—ideal for milsim, CQB, and beginner upgrades.

KV Variants:

- 2250KV (25,000 RPM) – Optimized for DMR builds

- 2520KV (28,000 RPM) – Balanced for all-purpose use

- 3350KV (37,000 RPM) – High-speed CQB/SQB performance

DTU

Designed to sync flawlessly with the BL-480 motor. No braking conflicts, just seamless performance—elevate your control.

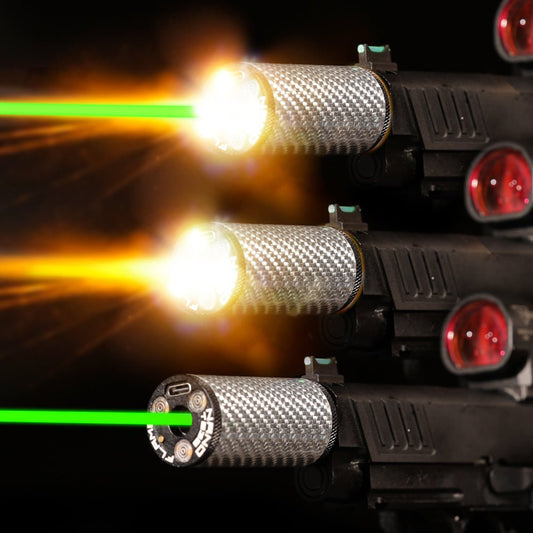

Tracer Unit

Pair with the airsoft for precision and visibility. Track every shot with unmatched clarity, only from T238.

Innovative Design for Maximum Comfort

Why Choose T238 Brushless Motor?

Proven in competition, trusted by pros. Built to outperform—plug-and-play, no gearbox tweaks needed.

Proven In Competitive Play

Trusted by Milsim and Speedsoft teams

Engineered For Extreme Performance

Outlasts brushed and budget brushless motors

Plug-and-play Upgrade

No gearbox modifications needed

The Ultimate Choice for Beginners

- Optimized thermal management

- Improved efficiency

- Faster response

Full 6061-T6 Aluminum Alloy Housing

- Precision machined via CNC

- Finished with anodized surface treatment

More Speed Options for Different Style Builds

- DMR

- STANDARD

- SPEEDSOFT

The T238 QRBLS-480 brushless motor is a high-performance upgrade for AEG replicas and gel ball blasters. Designed for competitive players and milsim enthusiasts, it serves as the entry-level model in the T238 Brushless Motor Series, featuring simplified operation with non-adjustable speed control. Key enhancements include: Optimized thermal management (5% lower operating temp vs. previous gen); Improved efficiency; Faster response, making it the ultimate choice for beginners.

Fully Compatible With T238 DTU Series

- No need to disable active braking

Compatibility Notes:

Gearboxes: V2/V3 (Verify shaft length before installation)

T238 Ecosystem: Works flawlessly with T238 DTUs (no braking conflicts)

Battery Systems: 2S/3S LiPo (XT60/T-Dean connectors recommended)

Ultra-Fast Response & Precision Control

- Response delay - As low as 5.6ms

- 32-bit MCU @ 48MHz - ensures smooth, real-time adjustments

- One-step buck-boost drive (No inefficient voltage conversion)

- NMB high-speed bearings (Rated for 60,000 RPM)

- ©Fully sealed housing (Dustproof, and shockproof)

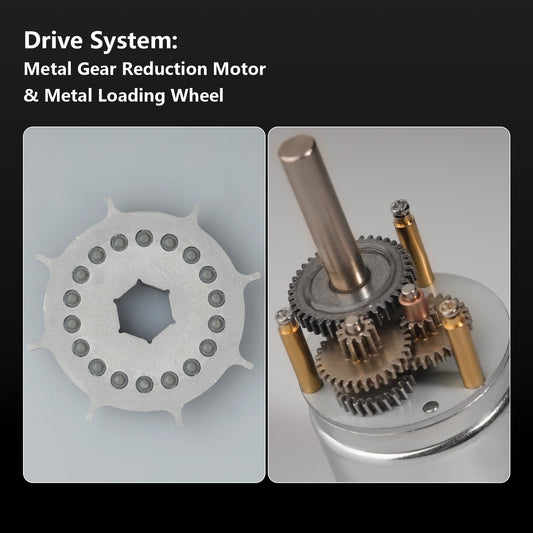

Premium Materials & Construction

- Hand-wound pure copper windings (Maximizes slot fill rate)

- Kawasaki 0.15mm ultra-thin silicon steel laminations (Minimizes core loss)

- 45SH-grade high-temp neodymium magnets (No demagnetization under heat)

- Alloy steel hardened shaft (Extreme durability & torque resistance)

Advanced Safety & Protection

T238 Brushless Motors feature smart protections like overheat, low voltage, rotor lock, and power failure stop—ensuring reliable and safe performance every time.

Undervoltage Protection

Overcurrent Protection

Overheat Protection

Stall Protection

Auto-detection Of Battery Cell Count Protection

(Prevents LiPo damage)

6-layer 2oz Copper PCB

(Superior current handling & EMI resistance)

- Ultra-fast response (No brush lag)

- High efficiency (Reduced energy loss)

- Low heat generation (Sustained performance)

- Maintenance-free (No brush wear or replacement needed)

Technical Specifications & Performance Display

At a Glance

What's in the Box

- Motor Type: Sensory Brushless (3-phase)

- Shaft Options: Long Shaft (LS) / Short Shaft (SS)

- Speed Adjustment: Disabled

- Input Voltage: 6V-12.6V (2S-3S LiPo)

- Bearing Type: NMB Japan (60,000 RPM rated)

- ESC Protection: Undervoltage, Overcurrent, Overheat, Stall protection

- Compatibility: V2/V3 gearboxes, T238 DTU series

- 1 * T238 QRBLS-480 Brushless Motor

Ready to Dominate the Field?

Upgrade to T238 Brushless Motor today and experience the future of AEG performance!

Critical Warnings

- Do not disassemble the motor

To prevent damage to the ESC (Electronic Speed Controller)

- Do not reverse battery polarity

Permanent damage to the ESC will occur.

- Incompatible with third-party ETUs featuring active braking

Permanent damage to the ESC will occur.

- Avoid prolonged no-load operation at maximum RPM

Risks rotor bearing failure.

- Maximum input voltage: 12.6V (3S LiPo)

Exceeding this voltage will damage the ESC.

Frequently Asked Questions

Frequently Asked Questions

Clarify any uncertainties you might have, ensuring a smooth and hassle-free experience for everyone.

Why aren't brushless motors compatible with other brands of ETU/Mosfet?

Because the brake function of other brands of ETUs can damage the ESC (control board) of brushless motors, unless the function can be turned off.Otherwise, it cannot be used.

What is the motor compatibility?

Warning!!! This brushless motor is best to use our brand ETU/MOSFET, not compatible with other brands of ETU/MOSFET, if the use of other brands of ETU/MOSFET causes motor failure, no warranty.

- Do not use ETUs of other brands!

- Do not power the motor in an unloaded state!

- Do not reverse connection of positive and negative poles!

- Do not use batteries greater than 12.6V!

Why does a 2520KV blue motor work in half-run but then often randomly stops working and will not run at full speed?

1. The motor is directly connected to the battery to confirm whether the motor is normal or not.

2. Replace the brushless motor in the gearbox to test and determine if the fire control is working.

What should I do when the motor is not working?

- Replace the battery and try it fully charged.

- Connect the brushless motor directly to the battery and test whether the motor is normal or not.

I have no way of knowing the RPM of the potentiometer, what should I do?

Example: I received the motor, but when I took it out of the box, the potentiometer used to set the RPM spun freely without any end stops or any legs. Therefore, I have no way of knowing the RPM of the potentiometer.

Cause of Failure:

- Do not rotate continuously; it will damage the end stops.

- The end stops have a weak cueing effect, so watch your strength when rotating them.

- Works fine without end stops and can be connected to a battery to adjust speed.

I have a helical gear ratio of 100:200 or 100:300 which is a high torque setup, what motor should I choose?

To maintain a decent trigger response, we suggest you start with the T238 brushless motor of 2980KV / 33000RPM Long type and gradually tweak the speed control adjustment knob to find the best sweet spot.